英文版正文723字,

预计阅读时长10分钟

中文版正文1000字,

预计阅读时长12分钟

Over the past few years, we’ve seen 3D printers used in increasingly creative ways. There’s been a realization that fundamentally, a 3D printer is a full-fledged, multi-axis robotic manipulation system—which is an extraordinarily versatile thing to have in your home. Rather than just printing static objects, folks are now using 3D printers as pick-and-place systems to manufacture drones, and as custom filament printers to make objects out of programmable materials, to highlight just two examples.

在过去的几年里,我们看到3D打印机的使用方式越来越有创意。人们已经认识到,从根本上说,3D打印机是一个成熟的多轴机器人操作系统,这是一个非常多功能的东西,在你的家里。现在人们不再只是打印静态物体,而是使用3D打印机作为挑选和放置系统来制造无人机,并使用定制的灯丝打印机来用可编程材料制作物体,当然这只是其中两个例子。

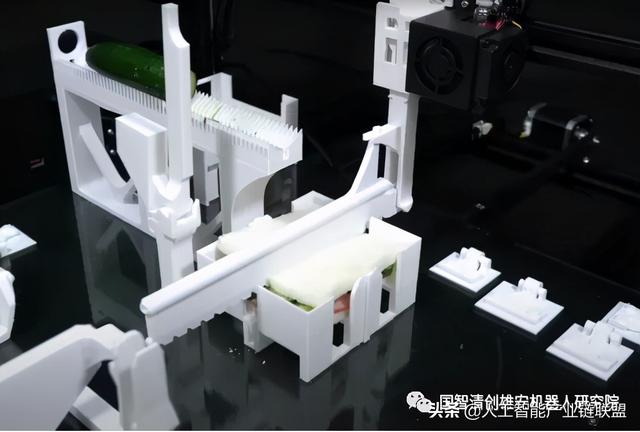

In an update to some research first presented at the end of 2019, researchers from Meiji University in Japan have developed one of the cleverest 3D printer enhancements that we’ve yet seen. Called Functgraph, it turns a conventional 3D printer into a “personal factory automation” system by printing and manipulating the tools required to do complex tasks entirely on the print bed. A paper on Functgraph, by Yuto Kuroki and Keita Watanabe, was presented at the Conference on 4D and Functional Fabrication 2020 in October.

日本明治大学(Meiji University)的研究人员对2019年底首次公布的一些研究进行了更新,他们开发出了迄今为止最聪明的3D打印机增强功能之一。称为Functgraph,它通过在打印床上打印和操作完成复杂任务所需的工具,将传统的3D打印机转变为“个人工厂自动化”系统。一篇关于Functgraph的论文,由Yuto Kuroki和Keita Watanabe在10月的4D和Functional Fabrication 2020会议上发表。

Far as I can tell, this is a bone-stock 3D printer with the exception of two modifications, both of which it presumably printed itself. The first is a tool holder on the print head, and the second is a tool release mechanism that sits off to the side. These two things, taken together, give Functgraph access to custom tools limited only by what it can print; and when used in combination with 3D printed objects designed to interact with these tools (support structures with tool interfaces to snap them off, for example), it really is possible to print, assemble, manipulate, and actuate entire small-scale facto

据我所知,这是一个bone-stock三D打印机进行了两个改动。第一个是打印头上的刀架,第二个是位于侧面的工具释放机构。这两件事结合在一起,使得Functgraph对定制工具的访问仅限于它所能打印的内容;当与设计用于与这些工具交互的3D打印对象结合使用时(例如,支持带有工具接口的结构来捕捉它们),它真的可以打印、组装、操作,带动整个小型工厂。

Yuto Kuroki, first author on the paper describing Functgraph, describes his inspiration for some of the particular tasks shown in the demo video:

Yuto Kuroki是描述Functgraph的论文的第一作者,他描述了他对演示视频中显示的一些特定任务的灵感:

前沿研究丨基于神经网络的机器学习方法在3D打印中的应用

得益于规模庞大的数据集、计算能力的提高和计算模型的优化改善,神经网络算法已成为机器学习算法中使用最广泛的模型。当前一个明显的趋势是,神经网络算法的经验成果正在向传统制造领域进行迁移,并对制造行业的产品设计、制造、质检到交付等价值链环节,产生

The future that Functgraph aims for is as a new platform that downloads apps like smartphones and provides physical support in the real world— the realization of personal factory automation.

When it comes to sandwich apps, there are many ways to look at recipes, but in the end, humans have to make them. I made a prototype based on the idea of how easy it would be if I could wake up in the morning saying "OK Google, make a breakfast sandwich."

Regarding the rabbit factory, it’s an application that mass-produces and packs rabbit figures. The box on the right is an interior box to prevent the product from slipping, and the box on the left is an exterior box that is placed in the store and catches the eyes of customers. This is a realization that the manufactured figure is packed as it is and ready for shipment. In this video, two are packed in a row, so in principle it is possible to make hundreds or thousands of them in a row.

The reason for making a prototype of an app to make a car is a strange story, but the idea is that if you send a 3D printer to a remote place like space, it will be able to generate what you need on the spot. Even if you’re exploring the Moon and your car breaks, I think that you can procure it on the spot again if you have a 3D printer, even without specialized knowledge, dedicated machines, and human hands. This research shows that 3D printers can realize individual desires and purposes unattended and automatically. I think that 3D printers can truly evolve into ‘machines that can do anything’ with Functgraph.

Functgraph的未来目标是成为一个新的平台,下载智能手机等应用程序,并在现实世界中提供物理支持——实现个人工厂自动化。

说到sandwich应用程序,有很多方法可以查看食谱,但最终,人类必须制作它们。我做了一个原型,基于这样一个想法:如果我能在早上醒来时说“好的,谷歌,做一个早餐三明治”,那该有多简单

关于兔子工厂,这是一个应用程序,大规模生产和包装兔子的数字。右边的盒子是一个防止产品滑落的内盒,左边的盒子是一个放置在店里的外盒,能吸引顾客的目光。这是一个认识到,制造的数字是包装,因为它是准备装运。在这个视频中,两个包装在一排,所以原则上可以使数百或数千他们在一排。

制作汽车制造应用程序原型的原因是一个奇怪的故事,但想法是,如果你把一台3D打印机送到太空这样的偏远地方,它就能当场生成你需要的东西。即使你在探索月球,你的车坏了,我想如果你有一台3D打印机,即使没有专门的知识,专用的机器和人手,你也可以在现场再次获得它。这项研究表明,3D打印机可以实现个人的愿望和目的无人值守和自动。我认为3D打印机真的可以演变成Functgraph的“无所不能的机器”。

这项工作与JPL为探索金星而开发的火星车有一些相似之处,当然,火星车不是一个软机器人,但它在类似的限制条件下工作,因为它不能依赖传统的电子系统进行自主导航或控制。事实证明,有很多聪明的方法可以利用机械(或者在本例中是气动)智能来制造具有相对复杂自主行为的机器人,这意味着在未来,软机器人(或者软机器人)可以在使用不合规系统不是一个好选择的情况下找到有价值的角色。

声明

本文素材来源于网络,由人工智能产业链联盟翻译编辑,不代表人工智能产业链联盟立场,转载请注明,如涉及作品版权问题,请联系我们删除或做相关处理!

编译:J<4

编辑:Zero